Engineers at Duke University have produced the world’s first fully recyclable printed electronics that replace the use of chemicals with water in the fabrication process. By bypassing the need for hazardous chemicals, the demonstration points down a path industry could follow to reduce its environmental footprint and human health risks.

Engineers at Duke University have produced the world’s first fully recyclable printed electronics that replace the use of chemicals with water in the fabrication process. By bypassing the need for hazardous chemicals, the demonstration points down a path industry could follow to reduce its environmental footprint and human health risks.

The research appeared online Feb. 28 in the journal Nano Letters.

One of the dominant challenges facing any electronics manufacturer is successfully securing several layers of components on top of each other, which is crucial to making complex devices. Getting these layers to stick together can be a frustrating process, particularly for printed electronics.

“If you’re making a peanut butter and jelly sandwich, one layer on either slice of bread is easy,” explained Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke, who led the study. “But if you put the jelly down first and then try to spread peanut butter on top of it, forget it, the jelly won’t stay put and will intermix with the peanut butter. Putting layers on top of each other is not as easy as putting them down on their own—but that’s what you have to do if you want to build electronic devices with printing.”

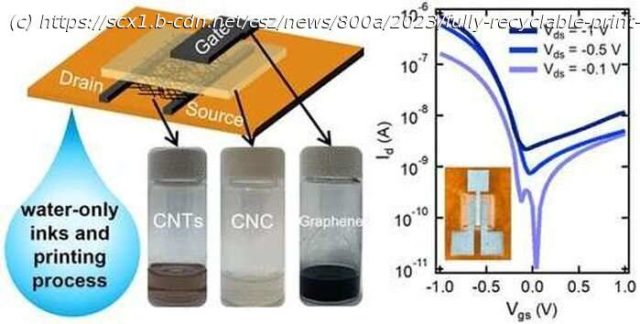

In previous work, Franklin and his group demonstrated the first fully recyclable printed electronics. The devices used three carbon-based inks: semiconducting carbon nanotubes, conductive graphene and insulating nanocellulose. In trying to adapt the original process to only use water, the carbon nanotubes presented the largest challenge.