By going vertical instead of staying flat, components can be stacked up, meaning much smaller footprints for our electronics – and we all want our devices smaller.

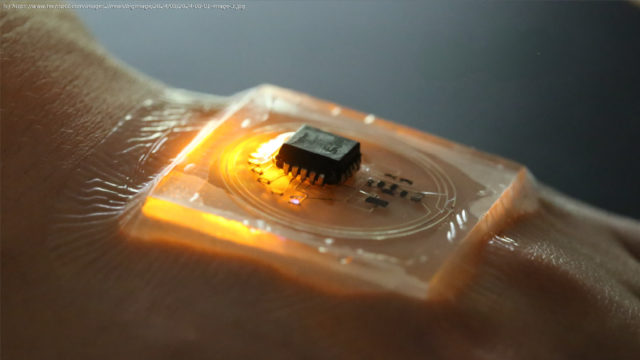

What just happened? Traditional printed circuit boards are pretty much stuck being flat and 2D. But a team of researchers from the National University of Singapore has leveled up circuit printing into the third dimension with a smart new technique called CHARM3D. And it’s not just 3D – these printed circuits can actually heal themselves, too.

By going vertical instead of staying flat, components can be stacked up, meaning much smaller footprints for our electronics – and we all want our devices smaller and sleeker these days. But achieving that 3D circuitry is a challenge with existing methods like direct ink writing (DIW). Those techniques use special composite inks that need support materials and are pretty viscous and slow.

CHARM3D takes a totally different approach by exploiting some clever material properties. It uses a metal alloy called Field’s metal made from indium, bismuth, and tin.

Start

United States

USA — software Using 3D printing to create 3D circuits: Researchers unlock self-healing boards