The 3D-printing hype ended years ago, but the threat of tariffs and the closing of the de minimis exemptions means that making your own stuff might actually hold some value.

Like many nerds, I have a 3D printer (or two) sitting around that I picked up at the peak of the hobby’s popularity. Surely, I’ll use this thing all the time, I thought. I’d never again purchase something I could make at home for free. That turned out to be a lie, because buying something is almost always easier than making something. That is, until Trump’s tariff threats.

Specifically (though not exclusively), the end of the De Minimis tax exemption changed the math for me quite a bit. Previously, this exemption allowed manufacturers to import products with a value under $800 without facing tariffs. This meant buying, say, a laptop or television might result in tariffs, but a gaming console or accessories would be safe. Without that exemption, even cheap items on Temu and Shein have become more expensive.

It made me wonder: Could my 3D printer be useful for something more than collecting dust? I sat down to do the math.Why 3D Printing (Sometimes) Wasn’t Worth It Before

When consumer-grade 3D printing first arrived, it was an expensive hobby. It also had only a few niche use cases, since everything had to be made of plastic. If the thing you wanted required, say, foam, glass, metal, rubber, or ceramic parts, your options were pretty limited. Plus, when you factored in the cost of buying the 3D printer itself, and the material to print with, suddenly the idea of making things for yourself becomes less attractive.

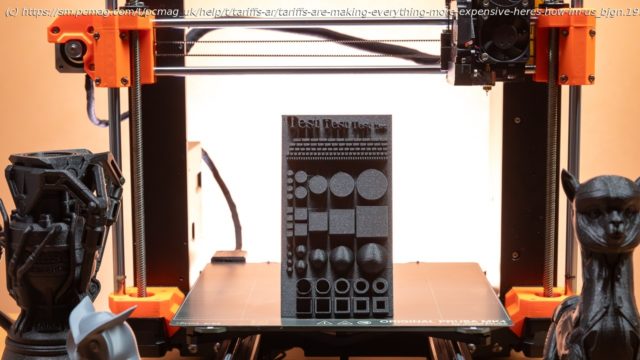

Early consumer 3D printers were also fiddly to work with. If you dabbled with 3D printing in the 2010s, you likely have horrible memories of recalibrating the print bed before every attempt at a print, or discovering that your room was a bit too warm and your print was warping as it was being made. It seemed everyone’s first print was a pile of hard spaghetti.

The core appeal of printing stuff you need in your home was washed away by the costs, both in terms of initial investment and time spent making it work. Even if you spent time learning how to work with 3D models or calibrate print beds, the average person just wasn’t going to compete with a mass production facility overseas that could churn out thousands of the thing you wanted and sell them to you for a pittance.

Home

United States

USA — IT Tariffs Are Making Everything More Expensive. Here's How I'm Using My Old...